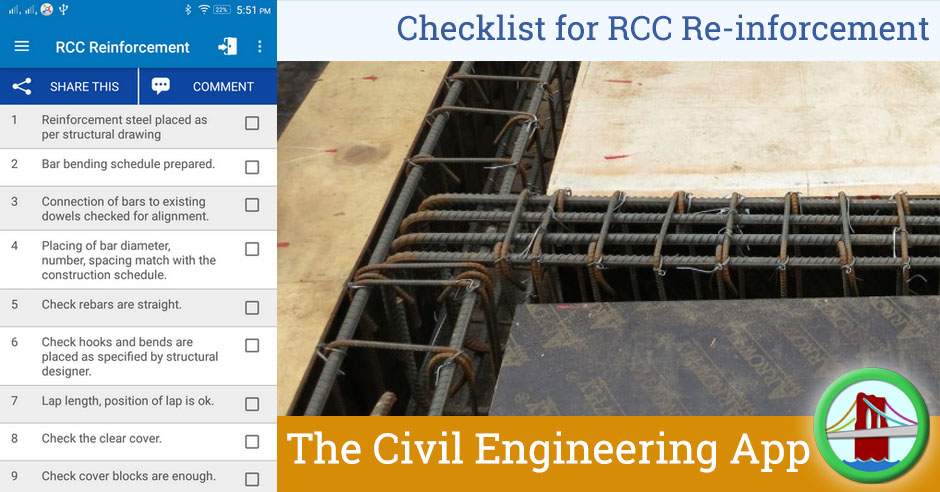

RCC Reinforcement frame must be properly assembled with proper bar diameters, spacing, external clearances etc. to ensure good quality and safety of RCC member. Following checklist helps ensure just that.

| Sr | Check Item | Done |

| 1 | Reinforcement steel placed as per structural drawing | |

| 2 | Bar bending schedule prepared. | |

| 3 | Connection of bars to existing dowels checked for alignment. | |

| 4 | Placing of bar diameter, number, spacing match with the construction schedule. | |

| 5 | Check rebars are straight. | |

| 6 | Check hooks and bends are placed as specified by structural designer. | |

| 7 | Lap length, position of lap is ok. | |

| 8 | Check the clear cover. | |

| 9 | Check cover blocks are enough. | |

| 10 | Maintain records and getting approval for additional reinforcement not shown in drawings. | |

| 11 | To check the construction joint for proper concrete bonding before placing reinforcement. | |

| 12 | Check for test reports for steel and approved brand. | |

| 13 | Identification color coding ok. | |

| 14 | Check the rebars are rust free. | |

| 15 | Check the rebars are crack free. | |

| 16 | Check minimum 1 inch clear distance is maintained between two bars. | |

| 17 | Check the rods are tied properly with binding wire. |