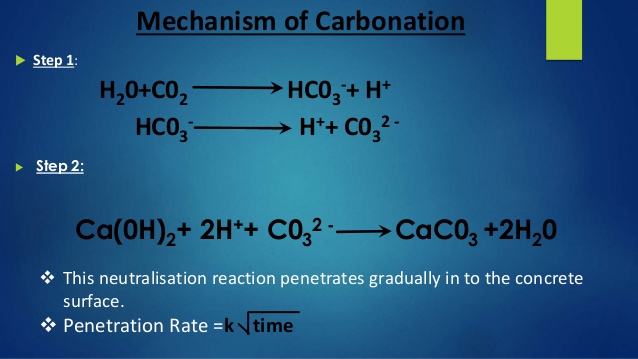

Although concrete typically begins its life at a highly basic pH of about 13, the pH values at exposed surfaces soon fall as reactions occur between carbon dioxide from the atmosphere and alkalis in the concrete—a process known as carbonation.

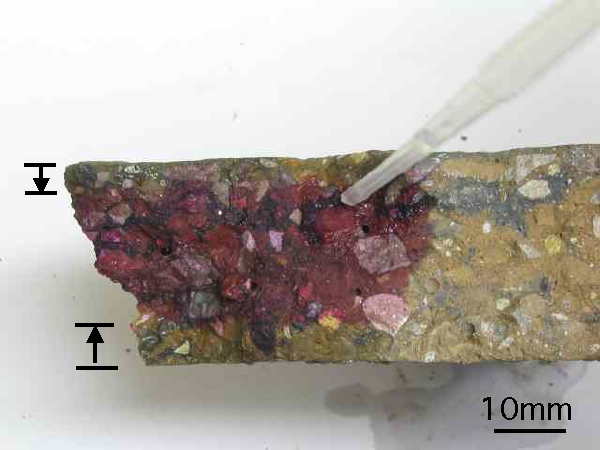

Over time, fronts of carbonated concrete, with pH values of about 8.5, advance below exposed surfaces. It may be necessary to determine the depth of this front, as carbonated concrete can allow corrosion of reinforcing steel.

This can be done by spraying a phenolphthalein indicator solution onto a fractured or cut surface of the concrete and noting the location of a color change. In this case, the color change occurs when the solution contacts a material with a pH of 9 to 9.5. The depth of the carbonation front can also be evaluated by using a drill to collect

samples at selected depths. In this case, the pH of the powdered samples can be evaluated using the standard test methods described in the following sections.

It may also be necessary to evaluate the pH of a concrete floor surface, as the adhesives used to install vinyl flooring or carpet tiles can be damaged when applied to substrates with pH values exceeding 9 (many flooring manufacturers won’t issue a warranty on their installed products unless the pH has been verified to be within acceptable ranges). Paragraph 5.3 in ASTM F 710-05, “Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring,” indicates a procedure to be used to test concrete floors for alkalinity.